hows does coalmill grinding

How Vertical Grinding Mills Work (Coal Pulverizer Example)

Vertical Mill Tutorial 1 : The Basics - YouTubeVertical Mill Tutorial 4 : Basic Milling Operations - YouTubeVertical Grinding Mill (Coal Pulverizer) Explained - saVReeCoal pulverisation with vertical roller mills Engineer LiveGrinding elements maximise pulveriser operating

Vertical Mill Tutorial 1 : The Basics - YouTubeVertical Mill Tutorial 4 : Basic Milling Operations - YouTubeVertical Grinding Mill (Coal Pulverizer) Explained - saVReeCoal pulverisation with vertical roller mills Engineer LiveGrinding elements maximise pulveriser operating

Vertical Grinding Mill (Coal Pulverizer) Explained - saVRee

IntroductionA Vertical Grinding Mill consists of The Following ComponentsHow Vertical Grinding Mills Work Electric Motor - to rotate the grinding table. The electric motor is often a three phase variable speed drive (VSD)induction motor, but designs vary.Reduction Gearbox- to reduce the rotational speed of the incoming motor shaft prior to a secondary shaft connecting to the grinding table.Grinding Table - a rotating round surface where the coal rests. Coal is crushed between the Electric Motor - to rotate the grinding table. The electric motor is often a three phase variable speed drive (VSD)induction motor, but designs vary.Reduction Gearbox- to reduce the rotational speed of the incoming motor shaft prior to a secondary shaft connecting to the grinding table.Grinding Table - a rotating round surface where the coal rests. Coal is crushed between the grinding table and grinding rollers. Grinding table surfaces are coated to resist erosion. If the grindin...Grinding Rollers- fixed rollers that grind the coal.展开选择时,新内容将添加到焦点当区域上方在savree上

Pulverizer - Wikipedia

A pulverizer or grinder is a mechanical device for the grinding of many different types of materials. For example, a pulverizer mill is used to pulverize coal for combustion in the steam-generating furnaces of coal power plants.

获取价格

How it Works: Crushers, Grinding Mills and Pulverizers

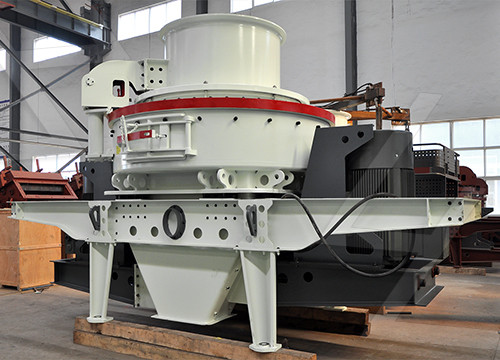

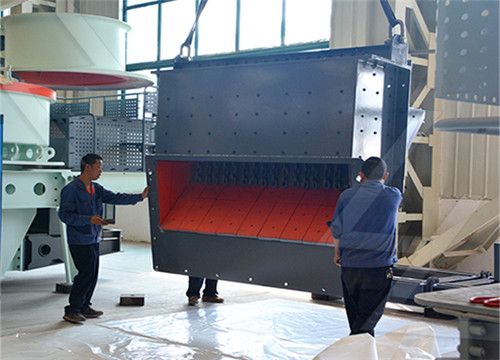

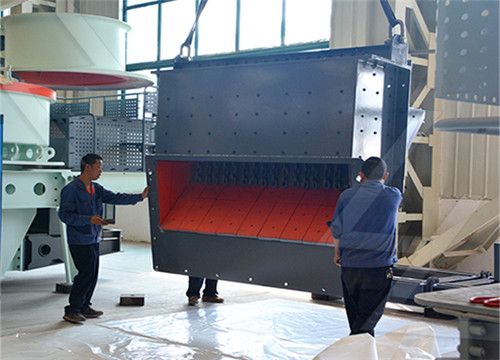

2017/6/2 Crushers, grinding mills and pulverizers are types of grinding equipment used to transform or reduce a coarse material such as stone, coal, or slag into a smaller, finer

获取价格

How A Coal Pulverizer Works - Coal Grinding Process - YouTube

观看视频4:592010/2/23 Here’s a 3D animation of how a coal grinding system works. Williams Crusher has the most advanced direct fired coal and pet coke pulverizing system in the fi...

获取价格

How does a Coal Mill Work? - ball mills supplier

A pulverizer coal mill works by grinding coal into a fine powder and then drying it in a hot air fan. The coal powder is then blown into a combustion chamber where it is burned to generate heat.

获取价格

Boiler Mill and Coal Pulverizer Performance GE Steam Power

Services for coal mill operations. We’re a world leader in coal pulverizing and boiler mill operations for horizontal and vertical boiler mills—committed to high-efficiency performance,

获取价格

How Does a Vertical Coal Mill Work - Coal Grinding Mill In

2024/3/16 Ultimately, the finely pulverized coal is transported via a burner pipe to the furnace of a power plant or cement kiln, where it undergoes combustion to generate heat for

获取价格

How does a coal mill work? - LinkedIn

2022/12/30 A coal mill works by grinding coal into a fine powder using large metal rollers. This process is used to create precise particle sizes as required by the application.

获取价格

Coal Pulverizer – Power Plant Pall Corporation

The grinding rolls are stationary in this design, while a worm gear drive rotates the ring (commonly known as the bowl). Powerful springs force the grinding rolls against the ring,

获取价格

Coal Mill - an overview ScienceDirect Topics

A simple energy balance model of the coal mill is derived in (Odgaard and Mataji 2006), this model is based on a more detailed model found in (Rees and Fan 2003).In this model the coal

获取价格

(PDF) Practical assessment of grinding capacity and

2019/1/1 This paper analyzes the effects of coal grindability and its characteristics on the grinding capacity and power consumption for beater wheel mill during exploitation in thermal

获取价格

Pulverizer - Wikipedia

The grinding force for coal pulverization is applied by a loading frame. This frame is connected by vertical tension rods to three hydraulic cylinders secured to the mill foundation. All forces

获取价格

Tower Mill Operating Work Index - 911 Metallurgist

2016/6/3 This device offers a significant power savings on wet fine grinding applications when compared to conventional tumbling mills. This paper describes the laboratory application

获取价格

Coal Mill in Cement Plant

The ball mill is a traditional coal pulverizer machine, which has been widely used since it was invented. In the cement plant, the new dry process cement manufacturing requires the

获取价格

Wet and dry grinding of coal in a laboratory-scale ball mill:

2020/1/1 Grinding test were performed in an XMQ-Φ240 × 90 laboratory-scale conical ball mill (Wuan Exploring Machinery Factory, Wuhan, China). For the wet- and dry-grinding tests,

获取价格

How to Process Coal into Pulverized Coal in 5 Steps?

2024/1/11 Make sure you have your coal feeders set up with the coal mill before you start crushing. It helps supply raw coal to the crushers or pulverizers for the first processing stage.

获取价格

The Effects of Moisture Content and Coal Mixtures

2014/2/1 Although many researchers [1,7,8,9,10,11,12,13,14,15] have investigated the efficiency of size reduction, there is still a need for the correct understanding the grinding energy efficiency in ...

获取价格

Wet and dry grinding of coal in a laboratory-scale ball mill: Particle ...

2020/1/1 As the grinding time increased from 1 min to 10 min, the dry grinding indicated a faster reduction of the average particle size (d 50) compared to the wet grinding. This is

获取价格

Energy-Efficient Technologies in Cement Grinding IntechOpen

2015/10/23 In this chapter an introduction of widely applied energy-efficient grinding technologies in cement grinding and description of the operating principles of the related

获取价格

Indirect Firing Coal Grinding Systems: Enhancing Efficiency and

Indirect firing coal grinding systems play a critical role in optimizing these aspects, especially in industrial applications such as power plants and cement manufacturing. This article explores

获取价格

Grinding Mills — Types, Working Principle Applications

2018/8/17 Further, the grinding mills can be categorized into three major types — rod mills, ball mills, and SAG mills. So, which one is for you? Well, the answer essentially lies in

获取价格

Ball Mill - an overview ScienceDirect Topics

The ball mill is used for the grinding of a wide range of materials, including coal, pigments, and felspar for pottery, and it copes with feed up to about 50 mm in size. The efficiency of grinding

获取价格

(PDF) Grinding in Ball Mills: Modeling and Process Control

2012/6/1 The feed material is typically composed of the BFRs and the catalyst, both in powder form. As the cylinder starts to rotate, the grinding balls inside the cylinder crush and

获取价格

Pulverizers 101: Part I - POWER Magazine

2011/8/1 Pulverizers prepare raw fuel by grinding it to a desired fineness and mixing it with the just the right amount of air before sending the mixture to boiler burners for

获取价格- машины для очистки песка от steet

- Хингингзолото очищающий хвостохранилище

- Подержанные горные породы в Европе

- самоцентрирующиеся вибрационный грохот

- С Шариковой Мельницей

- Цены на твердые минеральные измельчители

- Машины для измельчения камня

- Lea угля дробилки машины

- Перец Шлифовального Станок В Объединенных Арабских Эмиратах

- дробильные каменнаяменнаяы в луганске

- дробильная установка каталог гравий дробилка Китай

- белый цемент производители мини завод машин

- добыча угля стратегия

- Продажа Мобильных Дробилки Китай

- prinsip влияние kerja дробилка

- золотодобывающая дробилка б

- гидрозамок на конусные дробилки

- мини дробилкa для костeй уа

- Кремневые пескоструйные и щебеночные дробилки

- Снг Индия Каменная Дробилка

- Аренда Завода По Использованию Каменных Дробилов В Литве

- проектирование производства щебня

- allis чалмера щековая дробилка

- рока дробилки агента УЗБЕКИСТАНА

- золоторудных сепараторы добыча рок crusers на продажу